Application of sodium polyacrylate in mining

Sodium polyacrylate, while not a direct participant in mining processes, can have indirect applications in the mining industry through various supportive roles. SOCO®-produced sodium polyacrylate can be customized with parameters tailored to different application scenarios.

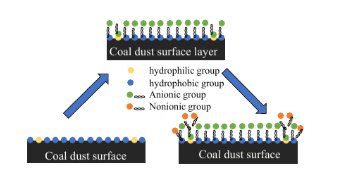

Dust Suppression Additive:

Sodium polyacrylate can be used as an additive in dust suppression products applied to mining roads, haulage ways, and stockpiles. By absorbing and retaining water, it helps control dust, providing a more stable and controlled environment in mining areas.

SOCO® polymer customizing the particle size of sodium polyacrylate allows for specific applications.【1】 Fine particles may be suitable for dust control, while larger particles might be more effective in certain soil stabilization applications.

Mining Dehumidification

Sodium polyacrylate (SAP), available in various forms such as powder, granules, or gel, is applicable to different scenarios in the mining industry. It can be easily dispersed around mining sites or directly applied to ores, providing a convenient solution for dehumidification needs.

It works by absorbing moisture from the surface of ores, preventing them from absorbing excessive moisture and thereby maintaining their ideal physical properties. After absorbing moisture, sodium polyacrylate forms a gel-like substance that effectively traps the absorbed water molecules, preventing them from evaporating back into the environment. Furthermore, its water retention capability prevents ores from becoming too dry, reducing issues such as dust generation or degradation of product quality. This process can be achieved even under pressure or low humidity conditions.

Water Retention for Reclamation:

In reclamation projects associated with mining sites, sodium polyacrylate can be used to improve water retention in the soil. This assists in establishing vegetation and promoting ecosystem restoration after mining activities have concluded.

Tailings Management:

While not directly involved in tailings treatment, sodium polyacrylate can indirectly support tailings management efforts. By stabilizing soil and improving water retention, it contributes to the overall stability and safety of tailings storage facilities.

Hydraulic Fracturing Fluids in Oil and Gas Exploration:

Although more relevant to the oil and gas industry, sodium polyacrylate is used in hydraulic fracturing fluids. As hydraulic fracturing involves extracting resources from the earth, this indirect connection highlights the cross-industry applications of the polymer.

SOCO® polymer adjusting the molecular weight of sodium polyacrylate can influence its water-absorbing capacity.【2】 This parameter customization is essential for applications such as a component in hydraulic fracturing fluids.

Environmental Remediation:

In instances where mining activities have impacted the environment, sodium polyacrylate can be used in environmental remediation projects. Its water-absorbing properties aid in controlling water movement, supporting efforts to address environmental challenges.

Infrastructure Construction:

Sodium polyacrylate may find indirect applications in the construction of infrastructure related to mining operations. For example, in road construction, its dust control properties can contribute to creating a stable and safe work environment.

It's essential to note that the indirect applications of sodium polyacrylate in mining are often tied to environmental and operational considerations. The polymer's ability to address dust issues, control erosion, and improve water retention contributes to creating more sustainable and environmentally friendly practices in the mining industry.

Comments

Post a Comment